[Tashiro Ironworks Co., Ltd. ] A team of engineers that responds to a variety of needs, from glass manufacturing facilities to prototype machines and machine assembly.

Business Contents

Glass Manufacturing Facilities

Tashiro Ironworks has contributed to the development of Japan’s glass industry since our founding in 1923.

The Glass manufacturing facilities introduced below were made possible thanks to our many years of experience.

Sheet Glass Manufacturing Facilities

Tashiro Ironworks possesses a record of

performance not only in glass for construction, but also for float

method facilities used in glass for liquid crystal. The glass products

which you see all around you everyday, even today, are produced by

facilities created using the technology of our company.

Record of Major Manufacturing

• Furnace back stay •Cooling duct

• Various types of cooling pipes

• Stirrer facilities

• Metal bath bottom casing • Metal bath roof casing

• Side sealing block • Dross box • Sealing gate

• Main-line washing machine for construction sheet glass • Motor facilities for laser cutting machine • Hopper gate

• Lehr facilities • Bottom cooling duct • Batch charger • Material blending dust collection facilities

• Metal bath bottom casing • Metal bath roof casing

• Side sealing block • Dross box • Sealing gate

• Main-line washing machine for construction sheet glass • Motor facilities for laser cutting machine • Hopper gate

• Lehr facilities • Bottom cooling duct • Batch charger • Material blending dust collection facilities

Factory Utility Facilities

Another important section of our company is utility facilities. Utility may be an unfamiliar term, but it refers to facilities that supply energy to various machine facilities.

Our company has many years of experience in piping facilities and supports the operation of many factories.

Record of Major Manufacturing

• Utility

facilities for FPD glass plants • Utility facilities for construction sheet glass

• Utility facilities for automotive glass plants

• Utility facilities for cathode-ray tube plants

• Utility facilities for automotive glass plants

• Utility facilities for cathode-ray tube plants

Processing Facilities for Automotive Glass

In terms of automotive glass, even front

glass only passes through variety of processing during production

such as that shown below. The technology of our company is used in

many of the facilities involved in such processing.

Record of Major Manufacturing

• Pre-pressing

facilities • Facilities for secondary

cooling after formation • Glass washing facilities • Gas furnace formation facilities

• Conveyors • Assembly and installation construction for roller hearth furnaces

• Post-furnace facilities (inspection facilities for after formation) • Inspection line • Pre-furnace facilities

• Gravity-type bending furnace • Glass forming facilities • Film pre-pressing facilities • Washing facilities

• Transportation • Forming facilities

• Post-furnace facilities (inspection facilities for after formation) • Inspection line • Pre-furnace facilities

• Gravity-type bending furnace • Glass forming facilities • Film pre-pressing facilities • Washing facilities

• Transportation • Forming facilities

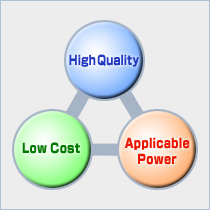

We use our fundamental technology which has been built up over many years as a base from which to respond to the needs of increasingly sophisticated and precise glass production technology. The features introduced below have helped Tashiro Ironworks to gain the trust of our customers.

Three Points of Tashiro Ironworks

High Quality

Our thorough quality management system has gained

us the trust of many customers. Our commitment to quality is backed

up by our strict monitoring of all processes without compromise.Low Cost

Corporate efforts to reduce costs to the lowest possible level are an important element of manufacturing. Our company strives every day to construct an efficient production system that provides our customers with benefits in terms of costs.Applicable Power

One of the strengths of Tashiro Ironworks is our ability to respond to various customer needs by utilizing the technology and know-how gained from many years of experience in glass manufacturing facilities. We employ a large number of staff possessing broad knowledge and advanced technology, and we perform various types of manufacturing including production of prototype machines and assembly of machines.

From Confidentiality to Quality Management

Another major feature of our company is our effort to protect the important facilities of our customers.

Our company has established a thorough confidentiality system to provide absolute prevention of any leakage of specifications or functions of facilities to external parties.

Furthermore,

our company implemented ISO9001 from an early date.

These kinds of measures bring peace of mind to our customers and allow them to trust us with their work.